There are robots available to help with most tasks now, so why not sewing? New start-up company Sewbo have jumped on this bandwagon with full force, and they have succeeded where others have failed in terms of robots making clothes. A big problem for many people who are using robots to try and make clothes is that clothes are not rigid and is very stretchy and is often very difficult for a robot to handle. The way Sewbo got around this was to temporarily stiffen the fabric using a polymer so that the robot was able to handle the material better.

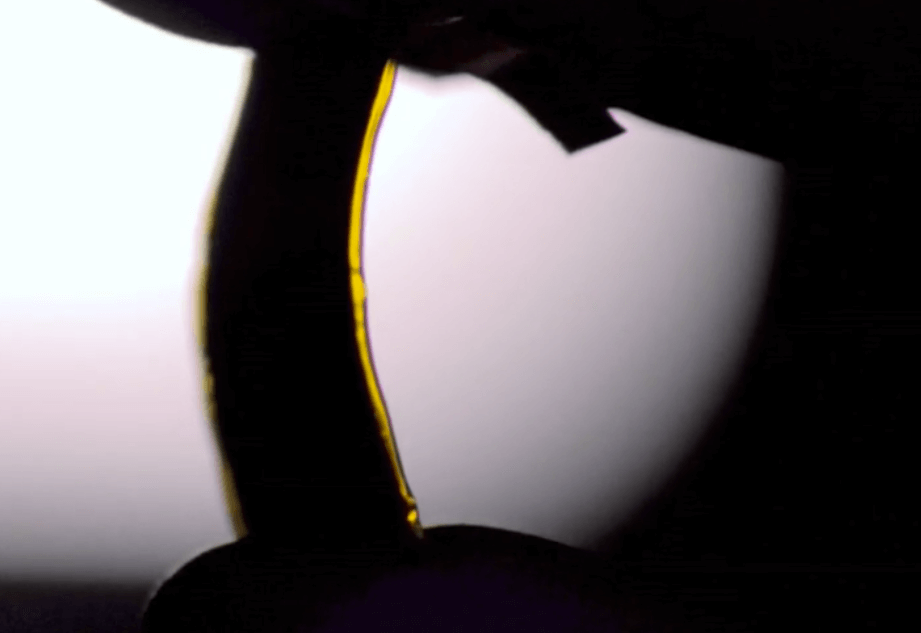

The water soluble polymer they used is already being used throughout the textile industry to stiffen yarn, so the team knew they would be able to use it safely. This polymer washes out very easily using warm water and will bounce back to its original shape and softness once dry.

Sewbo and its robotic sewing machine were developed back in 2014 when founder Jonathan Zornow quit his web developer job and invested $10,000 of his own money into making his dream a reality. And, it was worth every penny. Now the company has a robot that can fully assemble a T-shirt from start to finish that will work will almost any fabric, with the exception of leather and some waterproof materials.

Not one to mess around, Zonow has patents pending for his fabric stiffening process in 10 different countries and is now looking to produce more than just T-shirts. Sewbo has just signed a deal that will pilot the sewing system with Bluewater Defense who produce combat trousers for the U.S. military.

With the introduction of a sewing robot into the industry, massive savings can be made in terms of labor as garment manufacturing is very labor intensive. If just some of the processes can be, automated companies will save thousands.

More News To Read