There is a huge demand for rechargeable lithium-ion batteries. These are what power most smartphones, laptops, and digital cameras and as a result, the demand for them is huge. Unfortunately for us consumers, that means that the price of lithium is climbing. Not all lithium-ion batteries that come to the end of their life are currently recycled; some just end up on the top of a pile at the local landfill, wasting all those natural substances that were mined to make the battery in the first place.

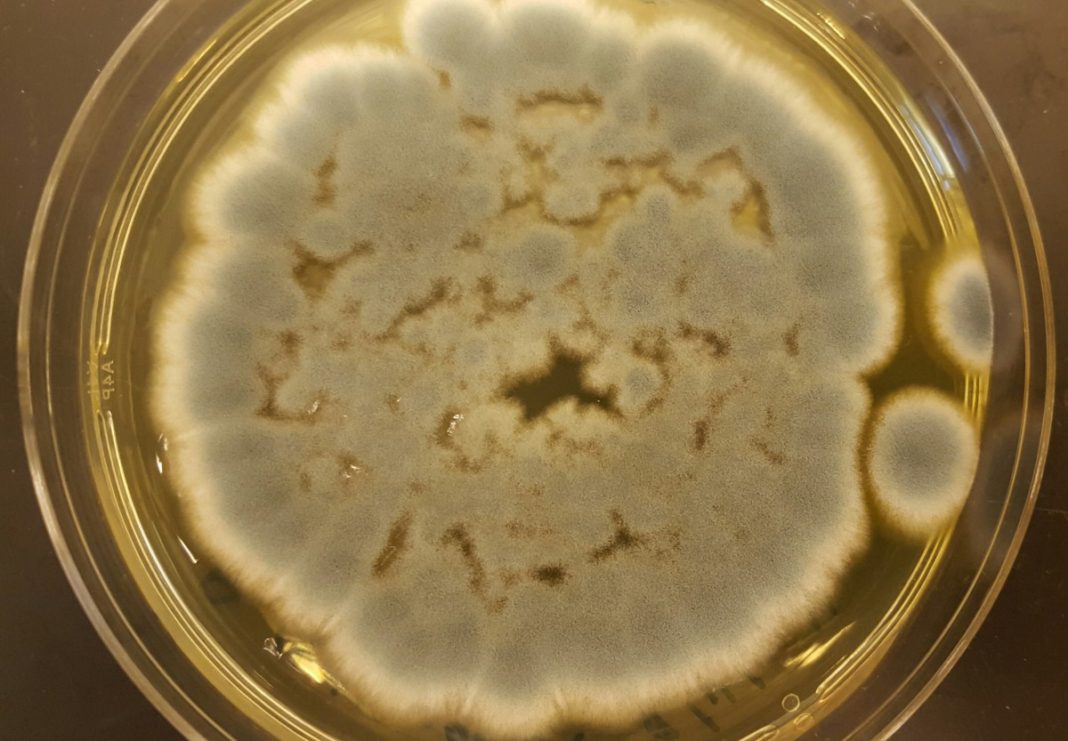

However, there could soon be a stop to all of that if Jeffrey A. Cunningham of the University of South Florida and team get their way. They have been studying how fungi are able to recycle rechargeable lithium-ion batteries. Traditional battery recycling involves using harsh chemicals such as hydrochloric acid and is very energy intensive. So instead, the team examined three common strains of fungi that can be found on moldy foods or water damaged buildings: Aspergillus niger, Penicillium chrysogenum, and Penicillium simplicissimum.

The research involved dismantling the existing lithium-ion batteries and pulverizing the cathode, which contains the lithium cobalt oxide (LiCoO2). The pulped substance was then introduced to the three different types of fungi. Then the fungi set to work naturally extracting the lithium and cobalt using its acidic compounds. The acids that are responsible for extracting the metals are oxalic acid and citric acid. They were found to be able to extract up to 85 percent of the lithium and 48 percent of the cobalt from the batteries. Although this is not quite a high percentage of the traditional hydrochloric acid method, it is much more environmentally friendly and uses far less heat.

The fungi recycling method is still in its very early stages of development, but if they do discover an effective way to extract the lithium and cobalt out of the mix once the leaching process is over and the fungi hold up during exposure to the toxic waste, then it could soon be a technique employed all around the globe. But, it is still a question of cost too. If this method is not very cost effective, then companies such as Umicore (Tesla’s battery recycling partner) will continue to take the upper hand.

More News To Read