According to a new study carried out by Lawrence Livermore researchers, a technology that was originally created to smooth out and pattern high-powered laser beams for the National Ignition Facility (NIF) can, in fact, be used in 3D printing. Metal objects can be printed faster than ever thanks to this technology which could revolutionize the industry as we know it.

The team’s finding was published last month in Optics Express as they describe how the new method, Diode-based Additive Manufacturing (DiAM) works. By using high-powered laser diodes, specialized lasers and laser modulators developed for the NIF, they were able to flash print a layer of metal powder as opposed to scanning a laser across each layer, as with conventional laser-based powder-bed fusion Additive Manufacturing (PBFAM) systems.

“By cutting the print time and having the ability to upscale, this process could revolutionalize metal additive manufacturing,” said Ibo Matthews, an LLNL scientist, and the paper’s lead author. “The illumination time savings, we estimate, is such that a one cubic meter build that would require 10 years of raster-scanned illumination to make would require only a few hours with DiAM because you can image layer at once. Printing with a gray-scaled image may also allow you to reduce residual stress because you can tailor the thermal stresses spatially and temporally.”

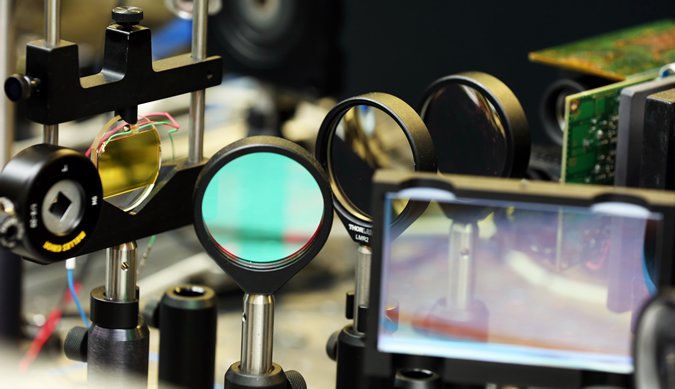

Matthews says the magic of the process is in the implementation of the specialized laser modulator called an Optically Addressable Light Valve (OALV). Similar to the way in which a liquid-based projector works, the OALV is used to sculpt high-powered laser light according to pre-programmed images, but unlike these conventional projectors, it’s un-pixilated and can, therefore, take much more power. It was originally intended as part of the LEOPARD (Laser Energy Optimization by Precision Adjustments to the Radiant Distribution) system at NIF but the team soon demonstrated it could be used for so much more.

James DeMuth, a former LLNL researcher led the demonstration that showed how the light valve could be used to print parts. “The DiAM project marries two technologies that we’ve pioneered at the Lab – high-power laser diode arrays and the OLAV,” explained John Heebner, the LLNL scientist responsible for heading the development of the OALV. “Given that we put all this time and development into this light valve, it became a natural extension to apply it to this project. We went through some calculations and it was clear from the outset that it would work (with 3-D printing). The ability to change a serial process to a parallel process is critical to ensuring that as parts increase in complexity or size that the patterning process speed can be increased to catch up.”

When it comes to DiAM printing, four diode laser arrays and a nanosecond pulsed laser are used to source the laser light. It’s then passed through the OALV where the image is patterned onto a slice of the 3-D part. The images get sent to the laser in a two-stage liquid crystal modulation process. Stage one involves sourcing the images from a CAD model and imprinting them onto a low-power LED source through the use of an ordinary, pixilated liquid crystal projector. Stage two involves the OLAV’s photoconductive layer being activated by the blue images, creating local conductive patches that transfer voltage across to the liquid crystal layer. The high-power laser is then modulated by the low power blue images and directed onto the build plane where it sets to work printing a whole metal layer in one go.

More News to Read

- Presenting The ‘Chit’ — The One and Only Chemical Hard Drive

- Abnormal Proteins Apparent in Alzheimer’s, Parkinson’s, and Huntingdon’s Patients

- What’s the Deal With Transformative Artificial Intelligence?

- Space Station Experiments Could Prove that Dark Matter Destroys Itself

- A New Method Tracks Unique Neurons and Brain Activity to Specific Actions in Zebrafish