It wasn’t that long ago that the first ever 3-D printer whirred into life. But since then, the world of 3-D printing and all that envelops it has swiftly grown stronger the more advanced technology has become.

Aside from the cool factor, 3-D printing solves so many problems. Manufacturing companies will never need to run out of vital components; maintenance staff could find faults, print a new part to replace the broken one, and fix the problem, without ever leaving the site. How much time would that save? Also, how cool would it be if a surgeon could literally print their tools in theatre as and when they needed them?

These are all things that are completely viable thanks to the developments in the world of 3-D printing. A. John Hart is an associate professor of mechanical engineering and director of the Laboratory for Manufacturing and Productivity and the Mechanosynthesis Group at MIT. He says that “3-D printing compels us to think how we develop, produce, and service products.”

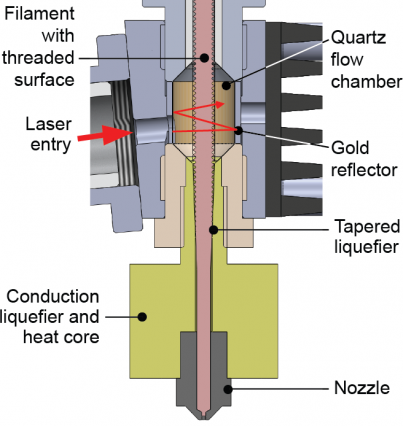

One of the most commonly used 3-D printing methods is called extrusion. Here, the filament is heated up until it melts. It is then fed through a nozzle that’s located in the printhead. When this printhead moves across the print bed, it deposits a small layer of polymer as per the prescribed pattern, layer upon layer, until the 3-D object is complete.

Thanks to the adoption of computer-aided design (CAD), designers are able to develop virtual 3-D models of their creation without the need for any molds or complicated machinery. But, even though 3-D printing has evolved a lot over the past decade, there’s still a lot more that can be done.

Two fairly recent developments in 3-D printing have come about with thanks to Hart, and they are the adoption of a 3-D printer that can produce objects faster than any other 3-D desktop printer available; and developing a process in which cellulose is used as a more cost-efficient, eco-friendly replacement for plastics.

Helping Hart and colleagues achieve this goal was Jamison Go ‘15, a mechanical engineer at Desktop Metal, and Adam Stevens, a doctoral student in Hart’s lab. They realized that the rates in which 3-D printers could work are limited by three things. These are: how much force the printhead could take as the material pushed its way through; how quickly the heat can be transferred to the materials; and how fast the actual printhead could move.

With those three things in mind, the group set to work developing the perfect 3-D printing machine. Because of its unique design, this 3-D printer can overcome the limit on heating and force that slows down the printing of other models on the market. In fact, tests carried out on the printer confirm it can deliver more than 2.5 x more force to the filament than most other standard desktop models available to buy.

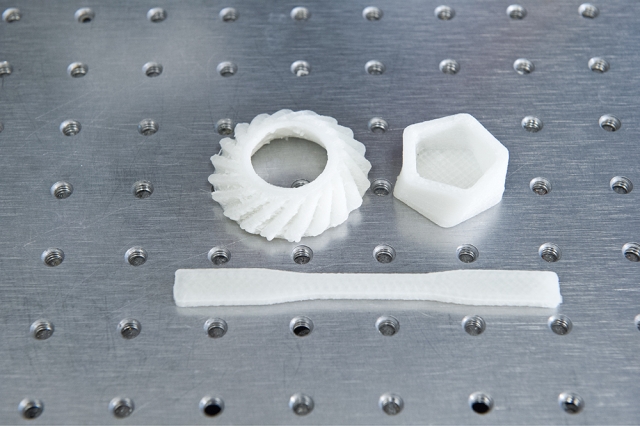

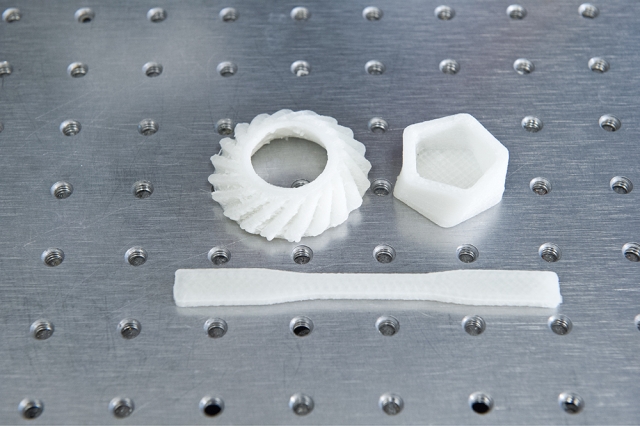

Photo courtesy of the researchers-MIT

Having such a high extrusion rate meant the researcher needed to develop a way that enabled the printhead to keep up the momentum. So, they created a mechanism that features an H-shaped, metal overhead suspension gantry in which to pull the printer belt back and forth.

Upon testing the 3-D printer’s capabilities, the researchers found it took just over 3 and a half minutes to print a pair of eyeglass frames and around 6 minutes to print a small spiral cup. They also tried printing more difficult items such as a helical bevel gear. While this took around 10 minutes the end result was a 0.2mm thick object that was both robust and well made.

To evaluate the printer even further and see how it compared against others the researchers printed the same object using various commercial desktop models. What they discovered was in order to achieve the same resolution, the commercial printers were around 10 times slower on average.

While the retail cost of the printer is still yet to be set, the prototype system cost around $15,000 to make, most of which comes from the motors and lasers. And for that reason, it’s unlikely to be replacing desktop printers any time soon. That being said, it should still be a comparable, cost-competitive product when holding up against other professional systems.

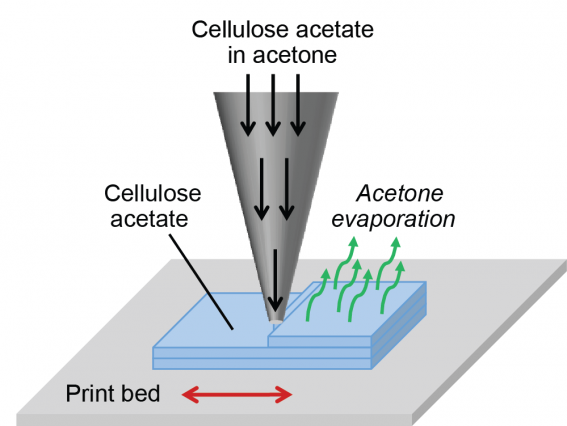

As well as being able to print accurate and fast, Hart’s vision for 3-printers also involves being able to process materials that are available in abundance and not harmful to the environment. And one of the ways he believes this is possible is through the use of cellulose.

Cellulose is a natural polymer has many advantages over most plastics used. Firstly, it’s much cheaper to use. Secondly, it’s mechanically robust. And thirdly, it’s biorenewable. And that’s just for starters. It’s also biodegradable and chemically versatile. But, there is one slight hitch – because of the abundant hydrogen bonding between the cellulose molecules, it’s not very effective when used in 3-D printing.

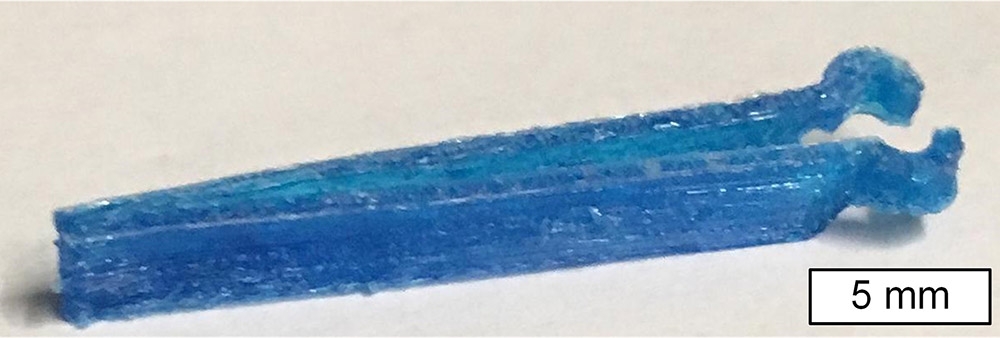

To solve that issue, the researchers decided to work with cellulose acetate instead. This chemically treated form of cellulose has far fewer hydrogen bonds than untreated cellulose and was much easier to work with.

Another area explored by the researchers was adding antimicrobial properties. Cellulose acetate disks were printed – some with and some without antimicrobial dye. An E. coli solution was then deposited on each one. While some of these disks were stored in the dark, others were exposed to fluorescent light. Results from the tests showed that those disks treated with the antimicrobial dye and exposed to light produced 95 percent fewer bacteria than the others.

Hart is hoping that with more people getting on board with 3-D printing, the capabilities of these machines will only get better. Last year he launched an online course aimed at professionals wanting to learn more about additive manufacturing which already has more than 1,200 students. He also teaches an increasingly popular graduate-level MIT class in additive manufacturing, as well as a 5-day MIT Short Program.