It’s an exciting time for engineers at NASA’s Marshall Space Flight Center in Huntsville, Alabama, as testing commenced on the agency’s first-ever 3D printed rocket component. The part itself is made up of two different metal alloys made using an advanced and innovative manufacturing process.

Credits: NASA/UAH/Judy Schneider

Previously, NASA engineers had been making the same part via a 3D printer but using only one metal, as printing with more than one metal is much more complex. “It is a technological achievement to 3D print and test rocket components made with two different alloys,” remarked Preston Jones, director of the Engineering Directorate at Marshall. “This process could reduce future rocket engine costs by up to a third and manufacturing time by 50 percent.”

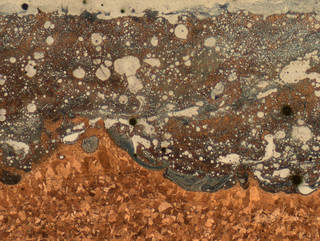

The prototype was low-pressure hot-fire tested more than 30 times in order to demonstrate the igniter’s functionality. This was carried out at Marshall’s Engine Components Development and Technology branch under the careful supervision of senior engineer Robin Osborne of ERC, Inc. of Huntsville, Alabama. Researchers then sliced up the prototype and examined it under a microscope only to discover that the two metals had created a strong bond by inter-diffusing. The igniter is one of the more complex parts of the engine, typically made up of many different materials. Normally these igniters are made by joining two types of metal together through a process called brazing, which is a highly labor-intensive and costly process.

“Eliminating the brazing process and having bi-metallic parts built in a single machine not only decreases cost and manufacturing time, but it also decreases risk by increasing reliability,” said Majid Babai, advanced manufacturing chief, and leader of the project. “By diffusing the two materials together through this process, a bond is generated internally with the two materials and any hard transition is eliminated that could cause the component to crack under the enormous forces and temperature gradient of space travel.”

In this prototype, a copper alloy and Inconel were fused together using a 3D printing process called automated blown powder laser deposition. Instead of making four individual parts and welding them together as done in the past, this igniter was made as one single unit. The igniter may be quite small, but it is still a great example of how this new technology can work and how much of a benefit it can be. No other machine has the ability to make a larger part that enables the inside to be made at the same time. “We’re encouraged about what this new advanced manufacturing technology could do for the Space Launch System program in the future,” said Steve Wofford, manager for the SLS liquid engines office at Marshall. “In next-generation rocket engines, we aspire to create larger, more complex flight components through 3D printing techniques.”

More News to Read

- Researchers Discover the Human Body’s Internal Clock

- Astronomers Detect Titanium Oxide for the First Time in Exoplanet WASP-19b

- Virtual Reality Travel Experiences That Will Blow Your Mind

- Astronomers Discover Fluctuations in Brightness of Unique Binary Star System

- Dark Energy Debate Takes Another Turn Thanks to New Supernova Analysis