Researchers at the University of Illinois’ Prairie Research Institute could be responsible for making biofuels both cheaper and greener thanks to a method that uses a processing catalyst made from palladium metal and bacteria. Biofuels are used as an alternative to petroleum based products and are made from renewable sources such as plants or algae. But, as good as biofuels are, traditionally, they’ve been very expensive to produce, hence why you don’t really see too much of them around. The reason that they cost so much to make is that the bio-oil that’s needed must be turned into liquid fuel at a refinery before it can be used. However, a new processing method developed by researchers over at the Illinois Sustainability Technology Center could be about to change all of that.

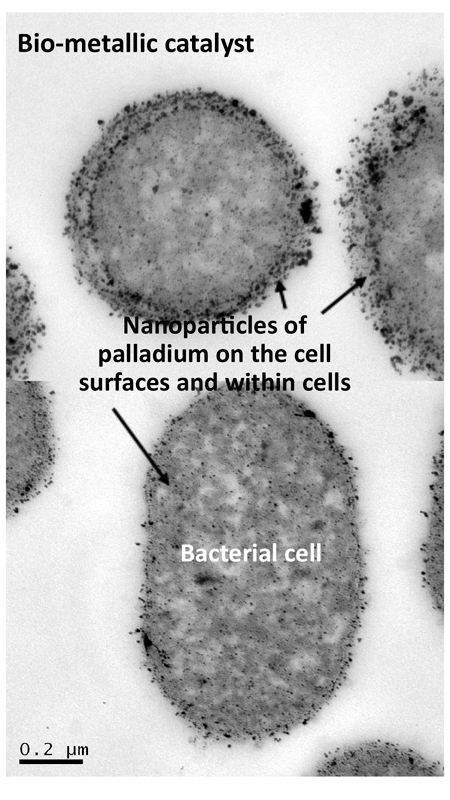

Photo credit: Lynne Macaskie

“Bio-oil forms from the same chemical reaction that forms petroleum,” says B.K. Sharma, one of the authors on the paper and researchers at Illinois Sustainability Center. “But what takes millions of years naturally in the ground takes only minutes in the lab using a process that is very similar to pressure cooking.” Using common bacteria and metal palladium the team have demonstrated how it is possible to make biofuels more efficiently. Sharma also advised how treating the bio-fuel with palladium as a catalyst during processing helps to get rid of any impurities while meeting clean-air requirements at the same time.

In order for the palladium to work the biofuel needs to be able to flow past it while processing. The team used bacteria cell masses in which to do this. “The oil can flow through the palladium-decorated bacteria masses as it does through carbon particles,” advises Sharma. During testing the team carried out a number of physical analysis to see if their method was capable of producing a liquid fuel just as good in quality as one made using a commercially produced catalyst. Sharma believes their product is just as good, if not better, than the commercially used one. “We were able to remove the oxygen and nitrogen impurities at a comparable rate, and yielded the same volume of product using our cheaper, greener catalyst as is observed using the more expensive commercial catalyst,” he says.

Of course, there is an advantage that the commercially used product has over Sharma’s, and that is that it can be used over and over without the need to undergo any extensive processing. The palladium-on-bacteria catalyst, however, will need to be processed before it can be reused. But that’s just a minor pitfall. “The fact that we have shown the potential of making refinery-ready crude oil from algae bio-oil using a catalyst that can be prepared from low-grade recycled metals and green and economical bacterial biomass proves that this is a very promising advancement. In addition, this bio-catalyst would work equally well in petrochemical processing,” says Sharma.

More News to Read