Because of the knee’s complex mechanism, it can be very difficult and expensive to repair if it does happen to become damaged in any way. It can also be very painful and debilitating. However, there may be light at the end of the tunnel for those suffering from a knee injury and that comes in the form of a 3D printed cartilage-like material that’s based on the hydrogel.

This new method of using 3D printed hydrogel allows bioengineers to create artificial parts that are specifically tailored to the individual’s requirements. By using technology to model a patient’s body parts from scans surgeons can create new hips, spinal vertebrae, and cranial sections that are a close enough match to the original. They’ve even used this same technique to produce details models of the human heart in which to plan complicated operations or create the perfect fitting mechanical implant.

Traditionally knees have proved very difficult to repair. One of the reasons for this is due to the ear-shaped pieces of cartilage called the menisci that sit inside the knee in between the femur and the tibia. These act as a kind of shock absorber that allows bending and moving smoothly and can take a lot of prolonged abuse. However, they aren’t indestructible, and when the menisci do get damaged it can result in a painful chronic injury and an increased risk of arthritis as healing time for the menisci is slow. What this means is that knees that become injured often require surgery, replacement, or removal of the menisci. But often these treatments are inadequate and the implants used are a poor match for the original when it comes to elasticity and strength.

“A meniscus is not a homogenous material,” says graduate student Feichen Yang. “The middle is stiffer, and the outside is a bit softer. Multi-material 3D printers let you print different materials in different layers, but with a traditional mold you can only use one material.” The hydrogel is the leading contender so far in which to print the meniscus, but the trick is to find one that can be printed and has the same properties as cartilage. Yang created one such hydrogel that seemed to work. Using a basic $300 printer, Yang successfully printed a replacement meniscus in just one day. Hopefully, this will demonstrate to others how viable this option is and soon we could be seeing 3D printed body part replacements used in many cases.

More News to Read

- Is the End of the Quantum Computer Race Finally in Sight?

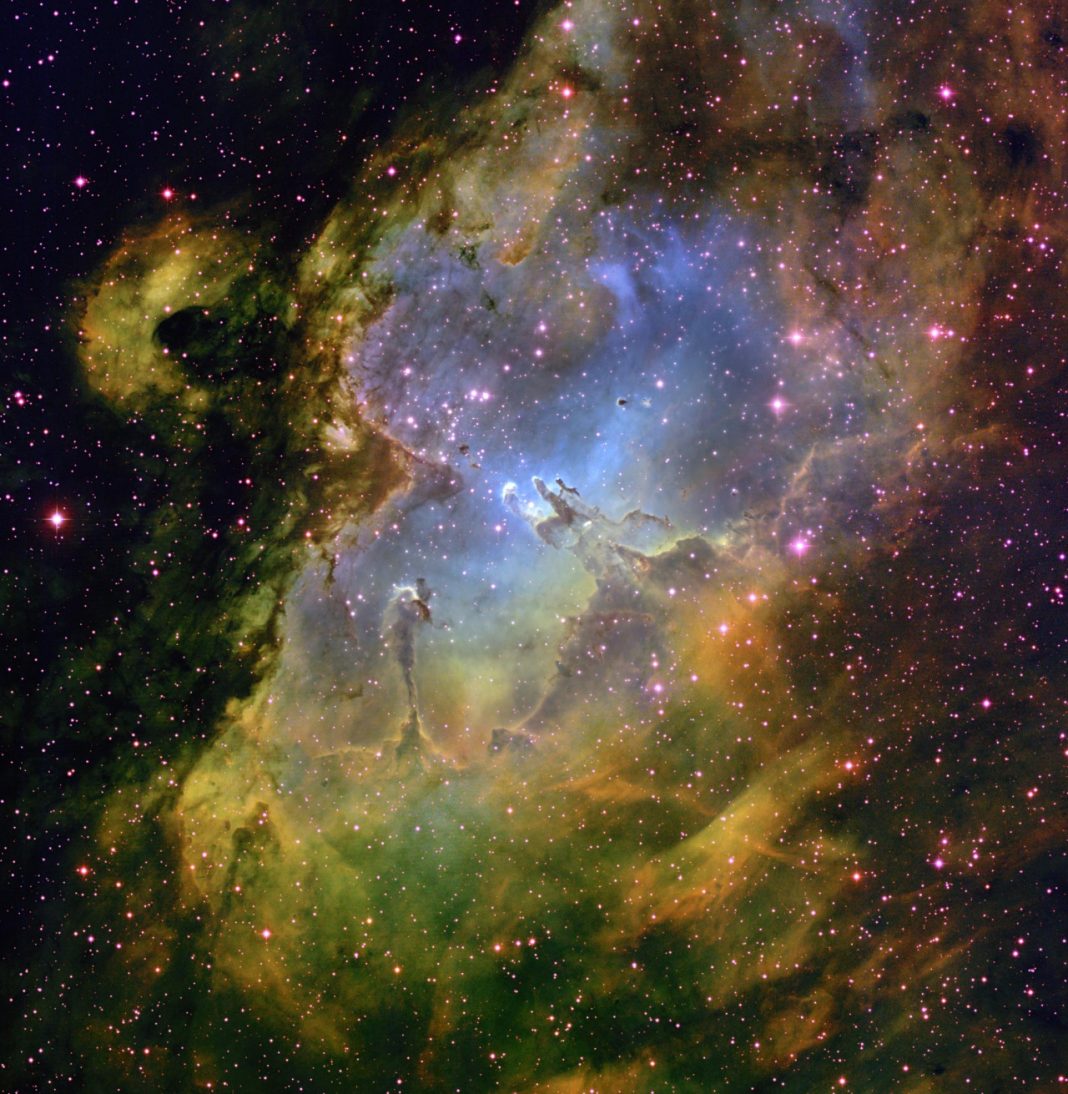

- Excitement Stirs as the James Web Telescope is Almost Ready to Go

- Move over Spielberg and make Way for this Script Writing AI

- Scientists Uncover a Higher State of Consciousness

- Self-Taught Artificial Intelligent Increases Heart Attack Prediction Rate Significantly