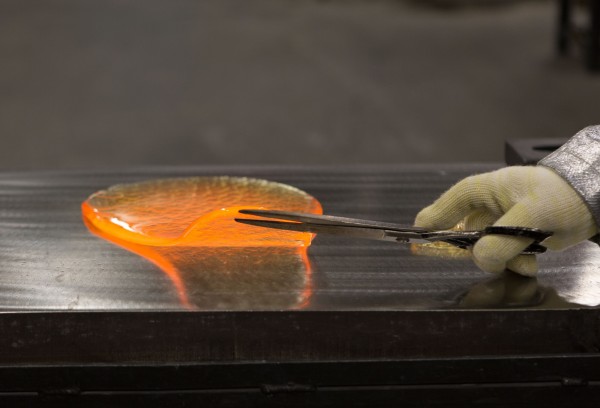

At Corning’s research center, located in upstate, rural, New York, workers are moving harmoniously together through the research furnaces as they play their part in helping to shape the future by creating flexible and lightweight devices. This process involves workers facing a blazing hot 1600 degree Celsius furnace, taking a crucible of molten glass from it, pouring out the contents and then shaping it before it has a chance to harden. It’s hot, hard work and not for the faint hearted at all. But, if done right, it may just change the products of the future.

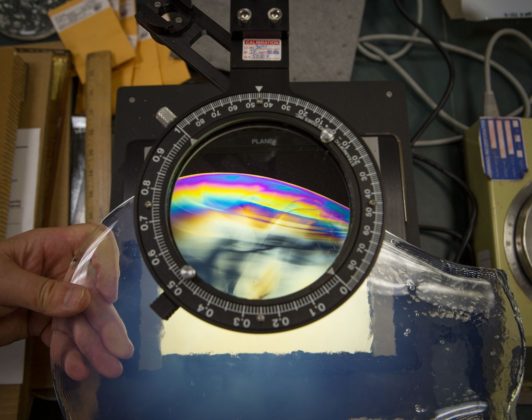

These researchers who are carrying out this hot task are working alongside Corning to see just how far they can push glass. Currently, the team prepares around 8 to 12 experimental mixes a day that they provide to the company’s scientists for testing. Tests they are carrying out daily include melting glass at different temperatures as well as seeing how different manufacturing methods will affect the various properties of glass. There’s a whole host of different machines at the facility, all of which play a different role. One machine repeatedly bends glass to see at the point it breaks, while another measures the pressure required to fracture the glass. As part of their research, the scientists found that stronger glass was more likely to fracture with a large number of cracks while weaker glass would only crack in a few places.

If they were able to find a way to make glass bendy yet difficult to scratch or break, this would mean a whole new load of products available on the market. Flexible glass could bring with it foldable cell phones or tablets, or turn car interiors and other curvy surfaces into touch-screen displays. While much of their research is being done using existing products such as Gorilla Glass, at least their manufacturing processes are new. And, with scientists constantly working on this, it won’t be long before we see a whole heap of flexible glass products coming our way. Just you wait and see!

More News To Read