Biodegradable plastic is a great planet saving material and the more we can produce of it the better. The problem is that currently, it’s expensive to mass produce. However, researchers from the University of Nebraska-Lincoln and Jiangnan University have come up with a plan to make the production of biodegradable plastic more affordable on a wider scale.

In doing the research, Yiqi Yang and colleagues discovered that by raising the bio-plastic fibers’ temperature really high, then allowing them to slowly cool, vastly improved their ability to resist both heat and moisture. By using this thermal approach, the researchers were able to bypass any expensive techniques and solvent needed to commercially manufacture an effective bio-plastic.

Current estimates suggest that around 90 percent of plastic used in the U.S. goes un-recycled, so if this new approach kicks off it could transform plastic recycling as we know it. The new method uses polylactic acid which is a biodegradable plastic that can be easily fermented from plants such as corn starch or sugar cane and is a great environmentally friendly alternative. However, there is a drawback to using polylactide and that is its susceptibility to heat up and gain moisture during manufacturing. Because of this, it’s of limited use in some areas, including textiles.

Researchers discovered long ago that mixing mirror image polylactide molecules, called L and D, could entice stronger molecular interactions to happen and overall better performance than just the polylactide on their own. But, trying to convince a large portion of these molecules to pair up is a nightmare and one that often forces researchers to come up with very costly and complex matchmaking methods. “The problem is that people couldn’t find a way to make it work so that you could use it on large scales,” explains Yang, Charles Bessey Professor of biological systems and of textiles, merchandising and fashion design.

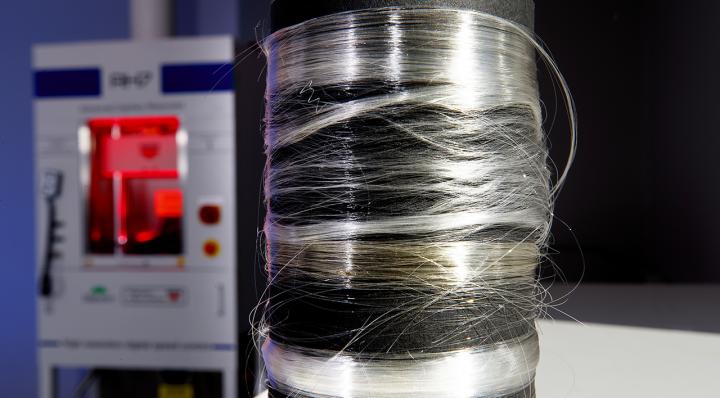

What the team eventually came up with involved mixing L and D polylactide pellets and spinning them into fibers then quickly heating them to around 400 degrees Fahrenheit. Those plastics that contained only the L or D molecules melted at about 100 degrees lower than the bioplastic. The bioplastic also succeeded in maintaining its structural integrity and strength after being held in 250-degree water, which is a process it would have to endure as part of some textile processes. Annually the textile industry produces around 100 million tons of fibers, so an alternative to the petroleum-based manufacturing employed currently would make a huge difference both financially and environmentally. Yang and his team will soon be scaling up their efforts to further demonstrate how this method will benefit industries and how it can be integrated into their current processes.

More News to Read

- Meet the Engineer Who 3D Prints Revolutionary Human-Robotic Arms

- Meteor Shower From Dead Comet Sighted Again

- Will Tesla 3 Pre-orders See the Light of Day and Will This Car Create…

- Future NASA Study Will Focus on the Ocean Worlds of the Milky Way

- Quantum Computer Programming: What You Need to Learn to Get Started?