The glass making industry has over 5000 years of existence. The art has been redefined, modified and revamped into countless classic styles. What remains unchanged through it all is the combination of minerals and sand under high temperatures of up to 1500 Degrees Celsius.

Competition is arising as a result of new trends. The additional of 3D printing has seen changes to the traditional rules of glass masking. The FFF layering of mold and glass to create objects is creating big competition between MIT and Micron3DP.

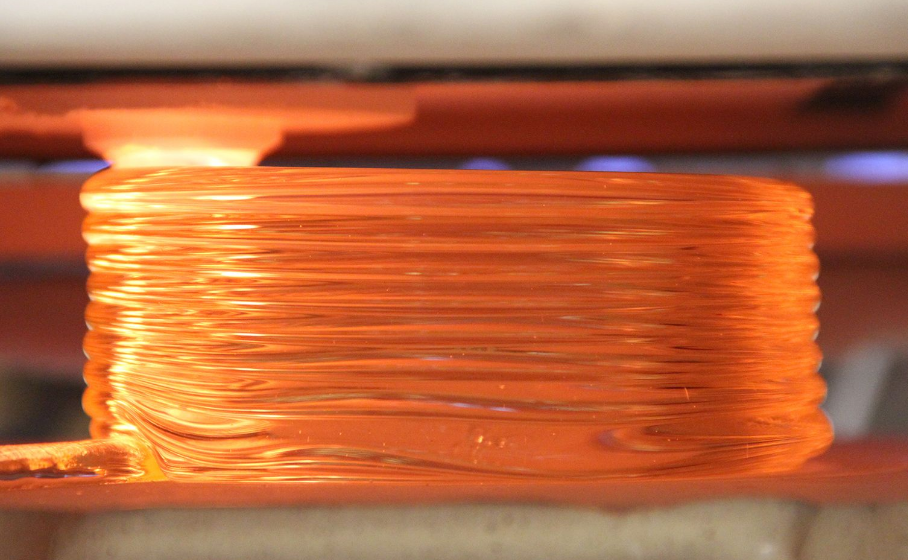

Micron3DP has come up with the latest development prints that house final layer thickness of 100 microns. This structure is a significant improvement on MIT’s 4000 microns. The new structure produces a more densely packed transparent structure. This makes it convenient as it can be manipulated in a number of ways.

The Micron3DP prints facilitate artistic expression that comes in handy when experimenting with complex geometric structures. The Micron3DP team is working towards acquiring the architecture, aerospace, and security industries. Seemingly, Micron printing in molten glass is expanding its capabilities.

The current Micron3DP printer is able to produce 200mm*200mm*200mm objects (approximately 5mm taller than a pint glass, same in length and width). The company needs to wake on keeping the molten glass from cooling quickly. Although this technology is still fragile, there is a lot of room for improvement, and 2017 will usher in changes. It seems the MIT vs. Micron rivalry has just begun.

More News To Read